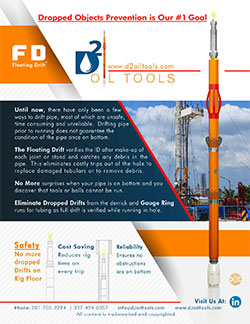

Our Mission

To help reduce future incidents of dropped objects, while saving you rig time and potential down hole problems.

Until now, there have only been a few ways to drift pipe, most of which are unsafe, time consuming and un-reliable. Drifting pipe prior to running does not guarantee the condition of the pipe once on the bottom.

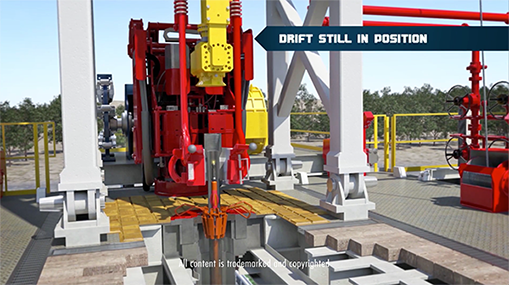

The Floating Drift verifies the ID after make-up of each joint or stand and catches any debris in the pipe. This eliminates costly trips out of the hole to replace damaged tubulars or to remove debris.

No more surprises when your pipe is on bottom and you discover that tools or balls cannot be run.

Eliminate dropped drifts from the derrick and gauge ring runs for production tubing as full drift is verified while running in hole.

The Floating Drift has been field tested for 1 Year on rigs prior to release to the public.

Who We Are

We are a small independently owned company with over 60 years of oilfield experience combined.

We have worked hard to bring a safer, more cost efficient way of drifting pipe while running in the hole.

Our number one goal for creating this product is Safety, Rig Cost and Efficiency.

No more sending the drift up in the elevators on a lanyard for the derrick hand to drop the drift with the possibility of hitting someone on the rig floor.

Don’t wait till your pipe is on bottom to find out you have ID restrictions caused during make-up or debris.

Eliminates the need to drop a drift out of the derrick, preventing a possible dropped object.

Prevents possible dropped object in well bore.

Reduces trip times when the need to drift out of the derrick arises (Running ball drop packers, gravel pack assemblies, TCP assemblies or any other BHA).

Allows the operator to know immediately after the joint/stand has been made up, if there is a damaged tool joint or debris in the pipe.

Can be used to drift the drilling risers while running. After running in the hole with production tubing, there is no need to run a gauge ring prior to performing slickline work, saving time and money.

If pumped down hole, it is easily fishable, millable and can be reversed out to surface with catch tool.

No special subs need to be placed in tubing string.

Eliminates the cost and time to Pickle the Pipe Prior to Frac Pack or Gravel Pack as the drift and junk basket removes the pipe dope.

.